Small Instruments, Big Role: Impurities Measurement in Refinery Water Monitoring

Small Monitoring Instruments Guard the "Final Checkpoint" of Refinery Wastewater: How to Test for Discharge Compliance?

In the entire refinery wastewater treatment process, every step—from grille interception of large impurities, to dissolved air flotation for oil separation, and then to biochemical degradation of dissolved pollutants—is aimed at purifying the wastewater. However, it is necessary to verify whether these treatments meet the standards and whether the wastewater can be safely discharged into the natural environment. This requires the "final line of defense"—wastewater discharge monitoring.

Monitoring instruments, though seemingly insignificant, continuously monitor the wastewater discharge outlet 24 hours a day. They use accurate data to determine whether the wastewater meets the discharge standards. This article explains the details of this "final checkpoint" and the working principles of these monitoring instruments.

First, Understand: Which Key Indicators Need to Be Tested?

Refinery wastewater has a complex composition, containing various pollutants such as oil, phenols, sulfides, and organic substances. The core task of monitoring instruments is to track several "key indicators" that directly reflect the pollution level. The most important ones are as follows:

1. Chemical Oxygen Demand (COD): A Core Indicator for Measuring Organic Pollution

COD refers to the amount of oxygen consumed by organic substances in water that can be oxidized and decomposed by strong oxidants. A higher COD value indicates a higher content of organic substances in the water and more severe pollution. Toxic organic substances in refinery wastewater, such as phenols, benzene, and hydrocarbons, will significantly increase the COD value. If the COD does not meet the standards, these organic substances will consume oxygen in the water after entering rivers and soil, leading to the death of fish and shrimp, and may also endanger human health through the food chain.

2. Petroleum Substances: A Characteristic Pollutant in Refinery Wastewater

Oil pollutants are inevitably generated during the refining process. Even after treatments such as dissolved air flotation, a small amount may remain. Petroleum substances floating on the water surface will form an oil film, isolating the contact between air and water and causing water hypoxia. At the same time, they may contain carcinogens such as polycyclic aromatic hydrocarbons, which pollute soil and groundwater. Therefore, the content of petroleum substances is a mandatory testing item for refinery wastewater monitoring.

3. Ammonia Nitrogen: A Factor Causing Eutrophication of Water Bodies

Ammonia nitrogen refers to nitrogen existing in the form of ammonia or ammonium ions in water. Ammonia nitrogen in refinery wastewater mainly comes from nitrogen-containing compounds in crude oil and by-products of the biochemical treatment process. If ammonia nitrogen is discharged in excess, it will cause eutrophication of water bodies after entering lakes and rivers, promoting the reproduction of a large number of algae, deteriorating water quality, forming "water blooms" and "red tides", and damaging the aquatic ecological balance.

4. pH Value: A Basic Indicator for Judging the Acidity and Alkalinity of Wastewater

The pH value of normal water bodies ranges from 6.5 to 8.5. Refinery wastewater may be acidic or alkaline due to the presence of phenols, sulfides, etc. Exceeding the pH standard will not only corrode pipelines and damage the living environment of aquatic organisms but also affect the acidity and alkalinity of the soil, leading to reduced crop yields.

Next, See How Monitoring Instruments "Accurately Capture" These Indicators?

Different indicators correspond to different monitoring principles. These compact monitoring instruments adopt specific technologies to quickly and accurately measure values:

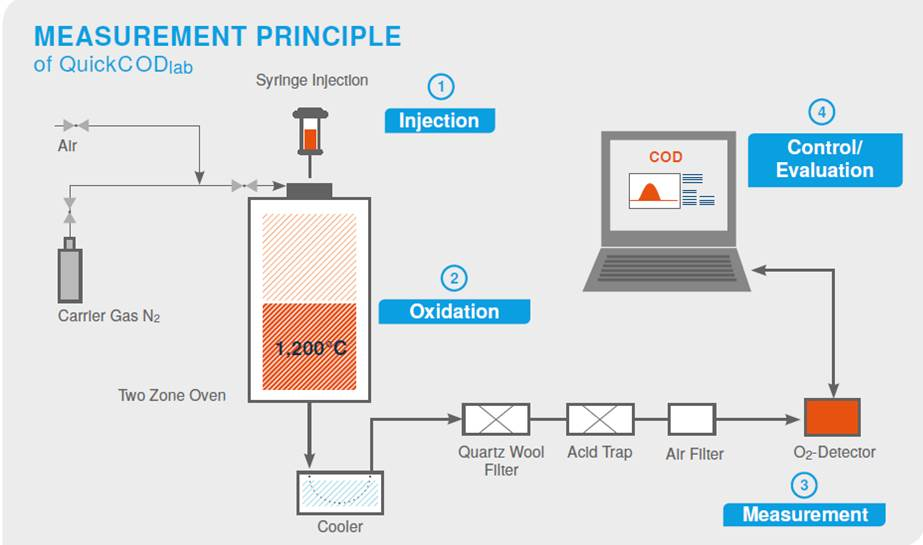

1. COD Monitor: Calculating Pollution Degree Through Oxidation Reaction

Common COD monitors adopt the "dichromate oxidation method": first, mix the wastewater sample with a strong oxidant (potassium dichromate) and fully oxidize the pollutants under high temperature and high pressure conditions; then, the instrument detects the residual amount of the oxidant after the reaction, and calculates the amount of oxygen consumed by organic substances in the water, i.e., the COD value. Current online monitors can also automatically sample, react, and calculate, outputting data in real time without frequent manual operations.

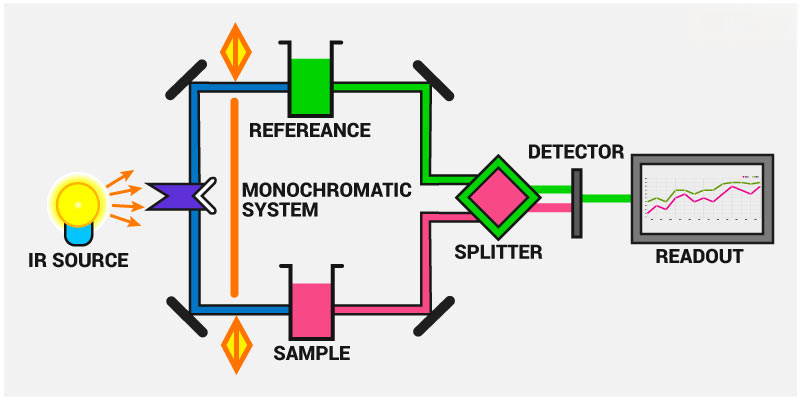

2. Petroleum Substance Monitor: Extracting Oil for Detection

Petroleum substance monitors commonly use the "infrared spectrophotometry": petroleum substances have the ability to absorb infrared rays of specific wavelengths, and the absorption intensity is proportional to the oil concentration. The monitor first extracts petroleum substances from the wastewater, then irradiates them with infrared rays, and accurately calculates the content of petroleum substances by detecting the intensity of the absorption signal. Some portable monitors can also be directly inserted into water samples to quickly read values, facilitating on-site inspections.

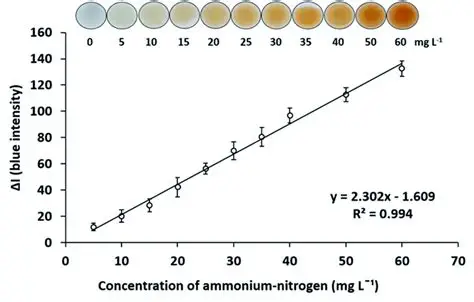

3. Ammonia Nitrogen Monitor: Color Development and Quantification Through Chemical Reaction

Most ammonia nitrogen monitors adopt the "Nessler's reagent colorimetry": after Nessler's reagent reacts with ammonia nitrogen in wastewater, a yellow compound is generated, and the higher the ammonia nitrogen concentration, the darker the yellow color. The monitor detects the absorbance of this yellow compound and converts it into the ammonia nitrogen concentration according to the standard curve. This method has high sensitivity and can detect trace amounts of ammonia nitrogen to avoid unmonitored pollutants.

4. pH Monitor: Measuring Acidity and Alkalinity Through Electrode Sensing

The core of a pH monitor is the pH electrode. When the electrode is inserted into wastewater, it generates different potential signals according to the concentration of hydrogen ions in the water. The instrument converts this signal into a pH value and displays it. To ensure accuracy, the monitor performs automatic calibration regularly to avoid data deviation caused by electrode aging.

Why Is This "Final Checkpoint" Indispensable?

Some may ask: why is monitoring necessary after multiple previous treatments? In fact, this step serves as a "dual guarantee"—both to ensure environmental safety and to ensure corporate compliance.

From an environmental perspective, even with a complete treatment process, water quality fluctuations may occur due to sudden changes such as raw material variations and equipment failures. Monitoring instruments can issue real-time warnings. Once the values exceed the standards, enterprises can immediately initiate emergency measures to prevent substandard wastewater from being discharged into the environment, thereby reducing pollution to soil and water sources.

From a compliance perspective, the state has clear standards for industrial wastewater discharge (such as the "Discharge Standard of Water Pollutants for Petroleum Refining Industry"). Enterprises must ensure that the water quality indicators at the discharge outlet continuously meet the standards. Monitoring data is uploaded to the regulatory platform of environmental protection departments in real time for supervision. Once the data exceeds the standards, enterprises will face penalties and may even be ordered to suspend production for rectification.

Conclusion: Small Monitoring Instruments Ensure Environmental Protection

Every step of refinery wastewater treatment is crucial, but the final monitoring checkpoint is the key line of defense to prevent pollution risks from entering the natural environment. These seemingly insignificant monitoring instruments provide a data basis for wastewater discharge through accurate data analysis, protecting the ecological environment and helping refinery enterprises achieve green production.

With the development of technology, monitoring instruments are becoming increasingly intelligent, capable of not only real-time monitoring but also remote data transmission and abnormal alarm functions. In the future, these monitoring instruments will become more accurate and efficient, providing protection for the green development of industry.