Space-Smart & High-Performance: Sinokle’s Niche Innovation in Oil Depot Water Treatment

In various oil storage facilities such as petrochemical plants, aviation fuel depots, and automobile gas stations, dewatering operation refers to a key process of separating water accumulated at the bottom of storage tanks from the oil phase during the extraction, transportation, storage, and processing of crude oil. The oil-containing wastewater generated in this process, which contains pollutants such as oil, suspended solids, etc., must be properly treated before discharge to reduce pollution and damage to the ecological environment.

At present, the main challenges faced in dewatering wastewater treatment at the above-mentioned oil depots are as follows:

1. Limited separation efficiency: Crude oil and water often form a tight mixture in storage tanks. Traditional processes that have been used for a long time, such as sedimentation, cyclonic separation, or membrane filtration, are often difficult to achieve complete oil-water separation. Improper operation will lead to residual water and impurities directly affecting oil quality.

2. Poor economic efficiency: Traditional separation technologies usually rely on large amounts of energy and chemical additives to achieve separation goals, resulting in increased treatment costs. Meanwhile, some technologies require large-scale facilities such as sedimentation tanks, which further increase land use and operating costs.

3. High safety risks: If water in storage tanks is not separated timely or sufficiently, it may cause abnormal fluctuations in tank pressure and temperature, and even induce tank deflagration accidents. Such situations not only endanger the stable operation of oil depots but also pose a major threat to the surrounding environment and personnel safety.

4. Potential environmental hazards: Wastewater generated during the treatment process may contain harmful components such as oil and heavy metals. Improper disposal will cause significant damage to the surrounding ecology. Therefore, strict environmental protection standards must be implemented in the dewatering process to ensure that discharged wastewater meets the standards.

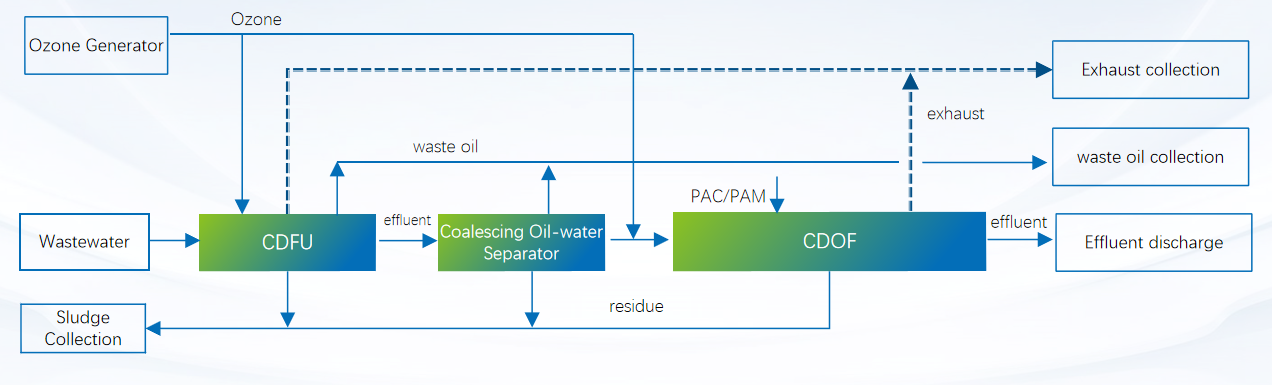

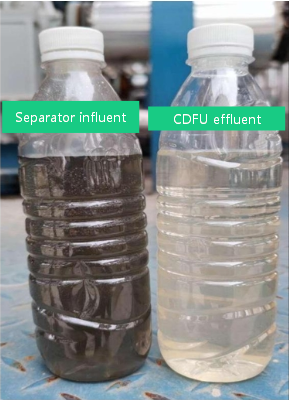

To address the above problems, Sinokle has developed a new treatment process centered on the Cyclonic Dissolved Gas Flotation Unit (CDFU), Coalescing Oil-Water Separator, and Cyclonic Dissolved Ozone Flotation Unit (CDOF). This process can significantly reduce pollution indicators such as oil, suspended solids, and chemical oxygen demand (COD) in wastewater, helping to achieve compliant discharge.

This process has the following significant advantages:

First, strong shock load resistance and stable effluent quality. The system can adapt to diverse water quality fluctuations and maintain efficient treatment status. The effluent indicators continuously meet stringent discharge standards, thus systematically solving the long-term industry problem of oil depot wastewater discharge.

Second, simple process, physical method-based, and environmentally friendly. The core of the process adopts physical separation methods, basically independent of chemical agents, which reduces the risk of secondary pollution. It features stable treatment effect, low sludge production, and simple subsequent disposal, making it a green and clean technology.

Third, fully automatic closed operation, small footprint, and easy operation. The system realizes full-process automatic closed operation, effectively shielding external interference and ensuring continuous and stable operation. The compact structure of the device requires less land, making it particularly suitable for places with limited space. High automation reduces manual intervention and maintenance intensity, improving operation and management efficiency.