Industrial Solutions for Electro-Desalting Wastewater: Demulsification, Oil Removal and Desalination

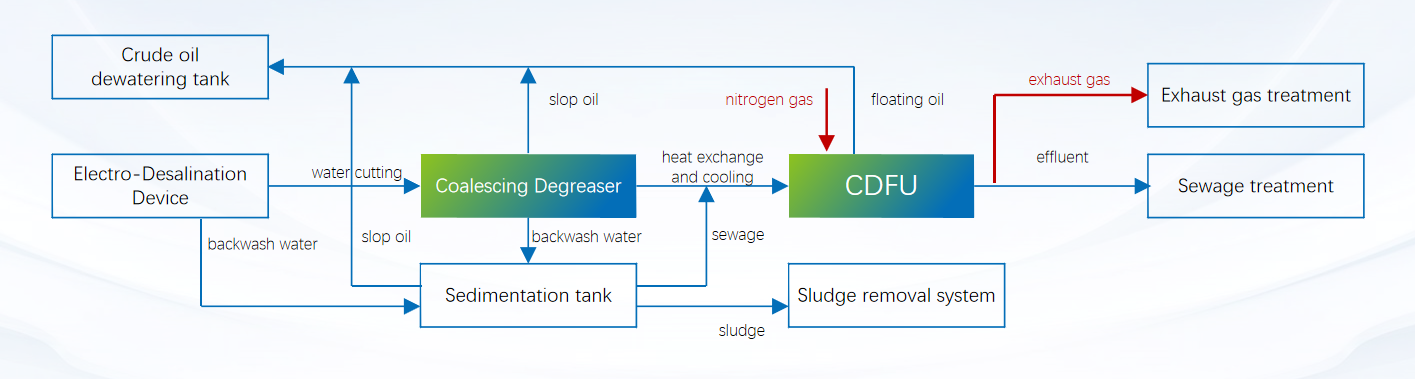

In the production process of oil refineries, electro-desalting is a crucial pre-treatment step for crude oil processing – it removes salts and some impurities from crude oil through electric field action to avoid corrosion and scaling of subsequent equipment. However, this process generates a "troublesome" type of wastewater – electro-desalting wastewater. Unlike ordinary industrial wastewater, it is not easy to treat, with core challenges focusing on three aspects: high salinity, emulsification, and oil content. The combination of these three "troubles" makes it a tough nut to crack in the refinery's wastewater treatment system. This article breaks down these three key pain points and explains how engineers resolve them one by one.

First, understand the source of the "troubles" in electro-desalting wastewater: Crude oil itself contains salts (such as sodium chloride and magnesium chloride), gums, asphaltenes, and various hydrocarbon substances. During the electro-desalting process, fresh water and demulsifiers are injected into the crude oil to enhance the desalting effect. The mixture of these substances forms wastewater with complex composition – salts are dissolved in the water due to dilution by fresh water, oil forms stable emulsions with water, and together with residual demulsifiers and gums, they jointly create this difficult-to-treat wastewater. Direct discharge or entry into conventional wastewater treatment systems will lead to soil salinization, water eutrophication, and damage to the microbial flora in conventional biochemical treatment, resulting in significant pollution hazards.

Pain Point 1: Emulsification – Oil-Water Separation Difficulty, Demulsification First Before Separation

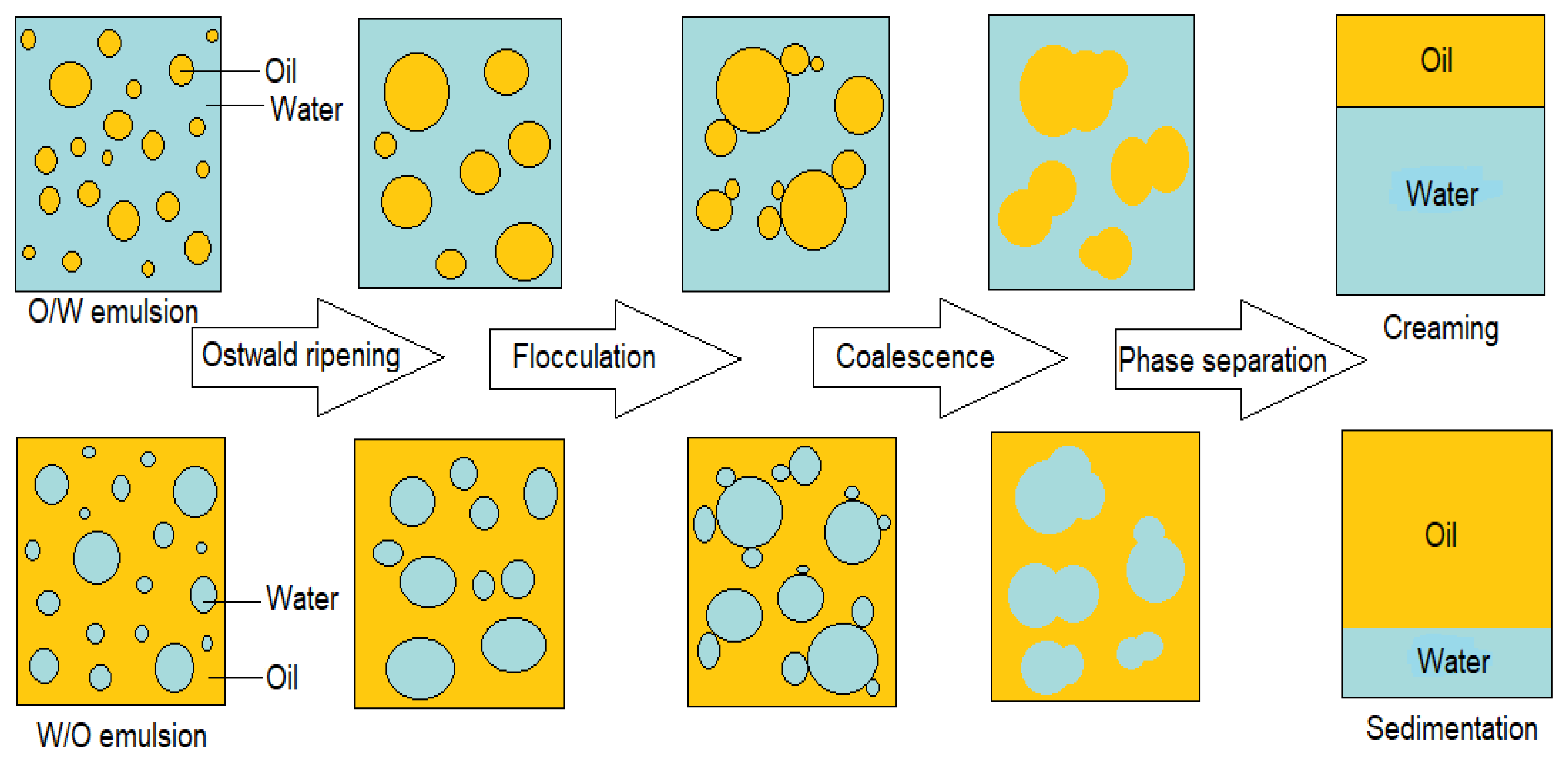

The first "trouble" of electro-desalting wastewater is emulsification. The wastewater here is not simply "oil floating on water"; instead, oil droplets are encapsulated in the aqueous phase, forming stable oil-in-water or water-in-oil emulsions. Oil and water are completely mixed and difficult to separate naturally. Without breaking this emulsified state first, subsequent oil and salt removal will be inefficient or even impossible.

Solution: Physical + Chemical Combined Demulsification for Oil-Water Separation

1. Chemical Demulsification: This is the most commonly used basic method. Special demulsifiers (such as polyether and polyester compounds) are added to the wastewater. Demulsifiers adsorb at the oil-water interface, destroying the stable structure of the emulsion, allowing small oil droplets to collide and aggregate into larger oil beads. This creates conditions for subsequent separation.

2. Physical Demulsification: For wastewater with high emulsification degree, physical assistance is required. Common methods include thermal demulsification (increasing temperature to reduce wastewater viscosity and weaken emulsion stability), electrical demulsification (using electric field to make oil droplets move directionally and aggregate), and ultrasonic demulsification (destroying the oil-water interface film through ultrasonic vibration). In industry, chemical demulsification is often combined with electrical demulsification to achieve higher demulsification efficiency and rapid initial oil-water separation.

After demulsification, most oil beads in the wastewater aggregate and float up, which are separated by scum scraping or oil skimming devices. The oil content in the subsequent wastewater can be reduced to several tens of milligrams per liter, clearing the way for subsequent treatment.

Pain Point 2: Oil Content – Residual Small Oil Droplets, Precise Capture Without Omission

After demulsification, although most free oil and dispersed oil are removed, the wastewater still contains residual small-sized dispersed oil and dissolved oil. If this part of oil substances is not completely removed, it will affect the effect of subsequent desalination processes, and may also form oil films in pipelines, leading to bacterial growth and corrosion. Therefore, precise capture of residual oil is the second key issue to be solved.

Solution: Advanced Oil Removal Technology to Target Small Oil Droplets

1. Dissolved Air Flotation (DAF) for Oil Removal: This is the core technology for treating small oil droplets. A large number of microbubbles are injected into the wastewater. The microbubbles adsorb on the surface of small oil droplets and carry them to the water surface, forming scum which is then scraped off. To improve efficiency, pressure dissolved air flotation is often used in industry – air is first dissolved in pressurized wastewater, and then suddenly depressurized to release air in the form of microbubbles. The microbubbles have smaller particle size and more uniform distribution, which can adsorb oil droplets more efficiently, further reducing the oil content in the wastewater to below 10 milligrams per liter.

2. Filtration for Oil Removal: For a small amount of residual oil droplets after DAF, further removal can be achieved through filtration devices. Common methods include quartz sand filtration and activated carbon adsorption filtration. Quartz sand removes larger oil droplets and suspended solids through interception, while activated carbon adsorbs residual small oil droplets and some organic pollutants by virtue of its strong adsorption capacity, making the wastewater clearer.

Pain Point 3: High Salinity – Difficult Salt Removal, Targeted Desalination to Ensure Compliance

After solving the problems of emulsification and oil content, the "ultimate trouble" of electro-desalting wastewater – high salinity – becomes the key target for overcoming. The salt content of such wastewater usually reaches several thousand to tens of thousands of milligrams per liter, far exceeding the conventional industrial wastewater discharge standards. Direct discharge of high-salinity wastewater will lead to soil salinization and damage the growth environment of crops; if it enters water bodies, it will increase the osmotic pressure of water, leading to the death of aquatic organisms. Therefore, desalination is a core link for the compliance discharge or recycling of electro-desalting wastewater.

Solution: Mainstream Desalination Technologies, Tailored to Water Quality

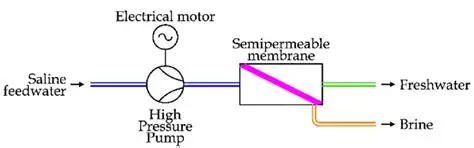

1. Reverse Osmosis (RO) Desalination: This is currently the most widely used membrane separation desalination technology in industry. Its core is a reverse osmosis membrane with selective permeability. Under high pressure, water molecules in the wastewater pass through the membrane, while salt ions (such as sodium ions and chloride ions) are retained, realizing the separation of water and salt. RO has high desalination efficiency, which can reduce the salt content to below several hundred milligrams per liter, and is suitable for treating electro-desalting wastewater with large water volume and medium salt concentration. However, pre-treatment must completely remove oil and suspended solids, otherwise the membrane surface will be contaminated, affecting its service life.

2. Evaporation Crystallization Desalination: For electro-desalting wastewater with extremely high salt content (such as exceeding 50,000 milligrams per liter), evaporation crystallization is a more appropriate choice. Water in the wastewater is evaporated by heating, and salt is gradually concentrated and crystallized, eventually forming solid salt residues. This method can completely separate salt; the treated water can be directly reused, and the crystallized salt can even be resource-reused after further purification. However, evaporation crystallization has high energy consumption and is usually suitable for scenarios with small water volume and extremely high salt concentration.

3. Electrodialysis Desalination: Using the selective permeability of ion exchange membranes, salt ions in the wastewater are moved directionally under the action of an electric field. Through the combination of cation exchange membranes and anion exchange membranes, salt is separated from water. Electrodialysis has relatively low energy consumption but slightly lower desalination efficiency than RO, and is suitable for subsequent advanced desalination of electro-desalting wastewater with low salt concentration.

Conclusion: Resolving Three Pain Points One by One, Turning Wastewater into Reusable Water

The treatment of electro-desalting wastewater involves resolving the two major challenges of emulsification and oil content through "demulsification + advanced oil removal" first, then selecting appropriate desalination technology according to the salt concentration, and finally making the wastewater meet the discharge standards. With the advancement of technology, the treated electro-desalting wastewater can now be recycled: it can be used as supplementary water for circulating cooling water in refineries and raw water for boiler feedwater, etc. This not only reduces pollutant emissions but also saves precious water resources, achieving dual environmental and economic benefits.

From the "troubles" of high salinity, emulsification, and oil content to the assurance of compliance discharge and recycling, the development of electro-desalting wastewater treatment technology is a vivid epitome of the green transformation of the refining industry. In the future, with the continuous emergence of more efficient and low-energy-consuming demulsification and desalination technologies, this "troublesome wastewater" will be endowed with more resource value, injecting stronger impetus into the green development of industry.