Core Pollutants in Oilfield Wastewater: Characteristics and Treatment Solutions

Wastewater generated during oilfield production contains three core pollutants: Chemical Oxygen Demand (COD), oil pollutants, and Suspended Solids (SS). Their presence directly affects the compliance discharge and resource utilization of wastewater. These three types of pollutants have significant differences in properties, and their treatment must follow the logic of "from shallow to deep, from easy to difficult": first remove visible suspended solids and floating oil, then separate stubborn emulsified oil and decompose some organic matter, and finally deeply degrade residual COD to achieve wastewater purification through step-by-step treatment.

I. Characteristics and Hazards of Core Pollutants

For efficient treatment, it is necessary to clarify the basic characteristics and hazards of the three types of pollutants:

• Oil pollutants: Including floating oil, dispersed oil, and emulsified oil. Floating oil floats on the water surface, dispersed oil exists as fine oil droplets dispersed in water, and emulsified oil forms a stable emulsion wrapped by surfactants, which is the most difficult to treat. Such pollutants will contaminate the surface of water bodies, block soil pores, and adhere to the surface of treatment equipment to affect operational efficiency.

• Suspended Solids (SS): Mainly solid particles such as sediment mixed during extraction, fracturing sand residues, and equipment corrosion products. Suspended solids will increase water turbidity, block pipelines and filtration equipment, and easily adsorb oil stains and organic matter, increasing the difficulty of subsequent treatment.

• COD (Chemical Oxygen Demand): Characterizes the total amount of oxidizable organic matter in water (such as extraction additives, soluble organic matter in crude oil, etc.). A higher COD value indicates a more serious degree of water pollution. Some of these organic matters are difficult to degrade, which will damage the water ecological balance and is a core indicator to measure the effect of wastewater treatment.

II. Step 1: Physical Separation of Suspended Solids and Floating Oil

Physical separation is a pre-treatment link for wastewater treatment, with the core goal of removing visible pollutants and laying the foundation for subsequent advanced treatment.

1. Gravity Separation

Wastewater first enters the oil separator, and natural separation is achieved by utilizing the density difference between oil and water: floating oil floats on the water surface due to its lower density than water and is collected and recovered by an oil skimmer; large granular suspended solids with higher density (such as sediment) settle to the bottom of the pool and are cleaned regularly. This process can remove more than 80% of floating oil and large granular suspended solids, and has the characteristics of simple process, large treatment capacity and low cost, making it a basic process for oilfield wastewater treatment.

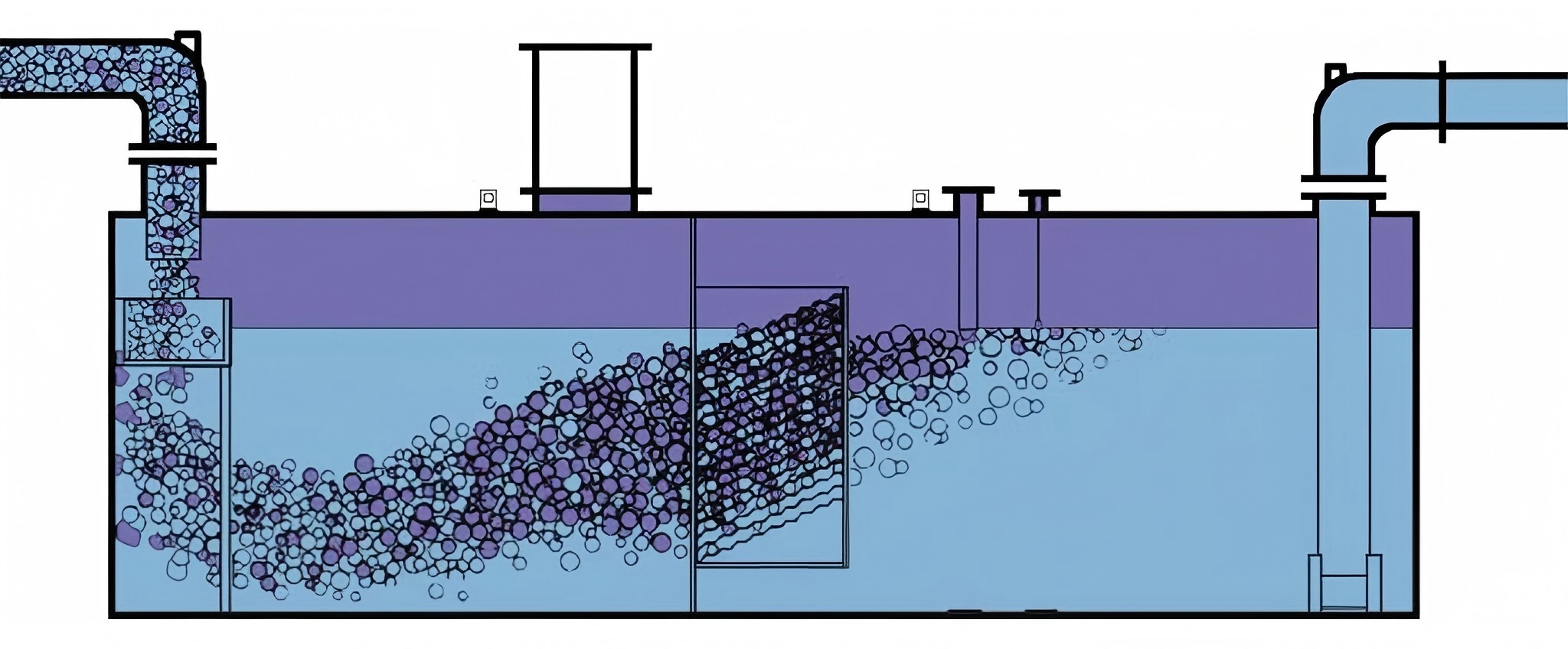

2. Air Flotation Separation

For fine suspended solids (particle size < 10 microns) and dispersed oil that are difficult to settle naturally, the air flotation process is used for treatment. By introducing a large number of microbubbles into the water, the bubbles adsorb on the surface of impurities and oil droplets, carry them to float up to the water surface to form scum, and complete the separation through scraping. In practical applications, a small amount of flocculant can be added to promote the aggregation of fine particles into large flocs, improving the separation efficiency, and the removal rate of suspended solids can reach more than 95%.

3. Pre-filtration Treatment

After gravity separation and air flotation treatment, a small amount of fine particles still remain in the wastewater. Filtration through filter layers such as quartz sand and anthracite further intercepts the residual fine particles, reduces water turbidity, and avoids clogging of subsequent advanced treatment equipment (such as membrane modules).

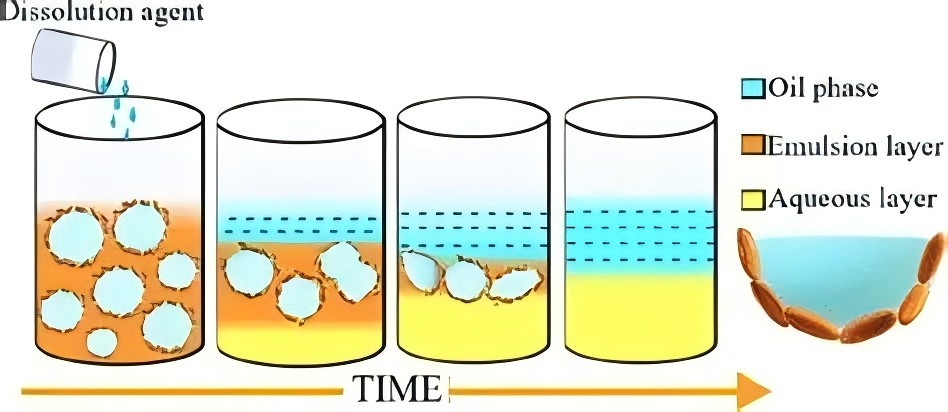

III. Step 2: Demulsification and Advanced Oil Removal of Emulsified Oil

After removing floating oil and large granular impurities, the residual emulsified oil in the wastewater has strong stability and cannot be separated by conventional physical methods. It is necessary to adopt a combined process of "chemical demulsification + physical separation" for treatment.

1. Chemical Demulsification

Demulsifiers (such as polymeric aluminum chloride PAC, polyacrylamide PAM and other polymer flocculants) are added to the wastewater. The demulsifiers adsorb on the surface of oil droplets, destroy the stable structure formed by surfactants, and promote the collision and aggregation of dispersed small oil droplets into large oil droplets, creating conditions for subsequent separation.

2. Advanced Separation

The demulsified oil droplets are further polymerized through a coalescing separator: the separator is filled with lipophilic and hydrophobic fiber materials, and the oil droplets adhere to the surface of the filler to quickly aggregate and grow, and finally float up for separation; for scenarios with high water quality requirements (such as oilfield reinjection), ultrafiltration membrane filtration can be used. The membrane pore size is only 0.01 microns, which can completely intercept the unseparated fine oil droplets, reducing the oil content of the effluent to below 1mg/L, meeting the reinjection or discharge standards. This link can also remove part of the organic matter adsorbed on the surface of oil droplets, reducing the subsequent COD treatment load.

IV. Step 3: Biodegradation and Advanced Oxidation Treatment of COD

After the first two steps of treatment, the wastewater has basically achieved no oil pollution and low turbidity, but the COD value may still not meet the standard. It is necessary to degrade the refractory organic matter dissolved in water through biodegradation or advanced oxidation technology.

1. Biodegradation

For biodegradable organic matter (such as some polymers, simple organic additives), the "anaerobic-aerobic" combined process is used for treatment. After the wastewater enters the bioreactor, anaerobic microorganisms first decompose macromolecular organic matter into small molecules, and then aerobic microorganisms completely degrade the small molecule organic matter into carbon dioxide and water. This process has low cost and strong environmental friendliness, and the COD removal rate can reach 60%-80%. It should be noted that most oilfield wastewater has high salt content, so salt-tolerant microorganisms need to be selected to ensure stable treatment effect.

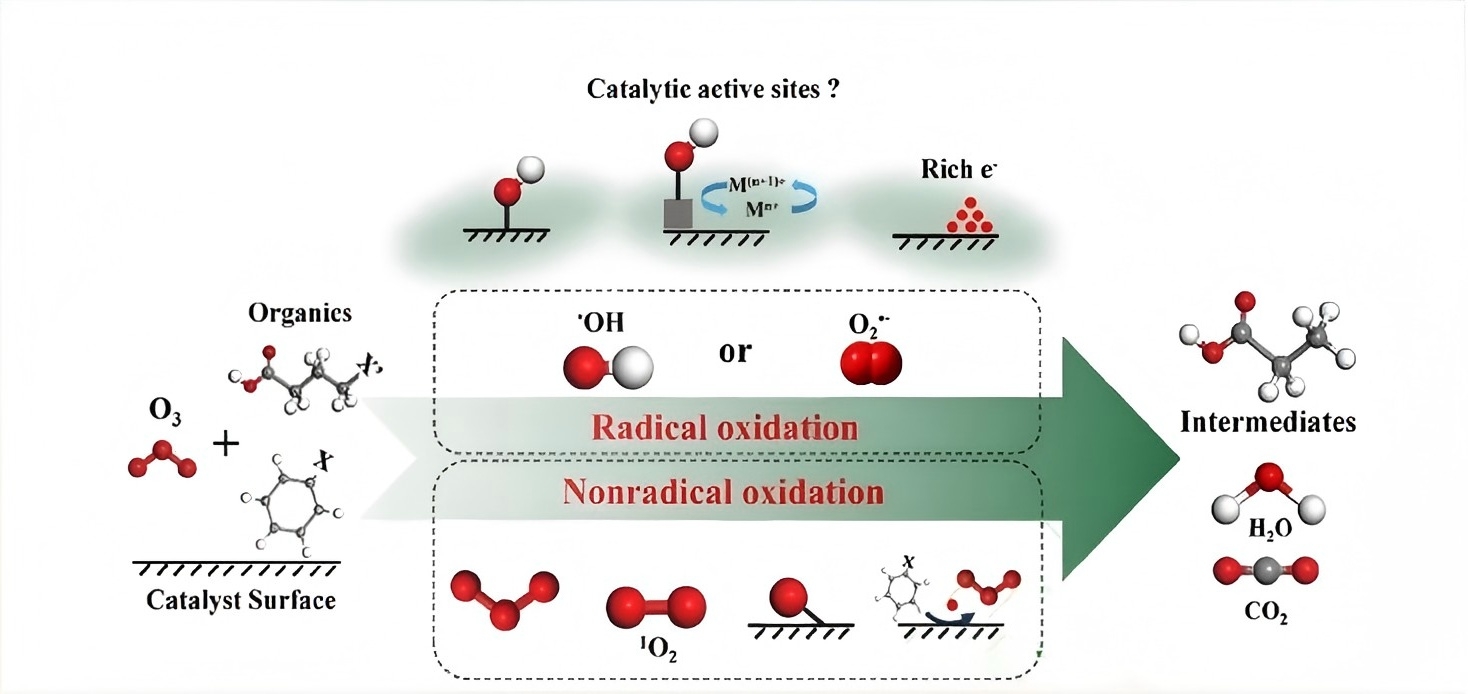

2. Advanced Oxidation

For refractory organic matter such as polycyclic aromatic hydrocarbons and complex polymers, advanced oxidation technology is used for treatment. Common processes include ozone catalytic oxidation, Fenton oxidation, electrocatalytic oxidation, etc. The core principle is to generate hydroxyl radicals (·OH) with strong oxidizing properties, which destroy the chemical structure of refractory organic matter and decompose it into harmless water and carbon dioxide. Taking Sinokle’s ozone catalytic oxidation as an example, it can efficiently degrade COD at room temperature and pressure, with a removal rate of 30%-60%, and at the same time remove chroma and odor synchronously without secondary pollution, which is suitable for advanced treatment of oilfield wastewater.

3. Advanced Polishing Treatment

Finally, the wastewater is subjected to advanced treatment through reverse osmosis (RO) membrane or activated carbon adsorption: the reverse osmosis membrane can retain the remaining trace organic matter and salt, and the activated carbon adsorbs residual pigments and odors to ensure that the COD value meets the discharge standard (for example, GB 8978-1996 Integrated Wastewater Discharge Standard requires COD ≤ 100mg/L). If it is used for reservoir reinjection, the water quality indicators need to be further improved.

V. Resource Utilization of Purified Wastewater

The oilfield wastewater that meets the standard after step-by-step treatment can realize resource recovery and utilization, improving the water resource utilization rate: first, reinject into the oil reservoir to supplement formation energy and improve crude oil recovery rate; second, use it for auxiliary links such as oilfield greening and equipment cleaning to save fresh water resources; third, after advanced desalination treatment, high-salt wastewater can be converted into industrial water to realize the resource recycling of wastewater.

Oilfield wastewater treatment is a collaborative application process of multi-disciplinary technologies such as physics, chemistry, and biology. With the improvement of environmental protection requirements and technological innovation, the treatment process is upgrading from "compliance discharge" to "resource utilization", which not only effectively controls pollution but also provides support for the green and sustainable development of the petroleum industry.