Beyond Traditional Dehydration: Sinokle's Chemical-Free Solution for Crude Oil Tank Farm Water Treatment

What is dehydration in crude oil tank farms?

Dehydration in crude oil tank farms refers to the process of separating water settled at the bottom of oil tanks from crude oil during the production, transportation, storage, and processing of petroleum. It aims to remove the settled water to maintain the quality and safety of crude oil.

What Are the Challenges Faced in Dehydration Treatment of Crude Oil Tank Farms?

The key challenges in dehydration treatment of crude oil tank farms are summarized as follows:

●Incomplete Separation: Crude oil and water are highly emulsified in storage tanks. Improper treatment will leave residual water and impurities, directly compromising the quality of oil products.

●High Treatment Costs: Traditional dehydration technologies for crude oil tank farms—including sedimentation, hydrocyclone, and membrane-based processes—require substantial energy consumption and chemical agent dosages to achieve effective separation.

●Safety Risks: Delayed or incomplete dehydration can cause unstable pressure and temperature inside storage tanks, which may even trigger tank explosion accidents.

●Environmental Pollution Risks: Wastewater generated during the treatment process contains harmful substances such as oil and heavy metals. Improper disposal of this wastewater will result in severe environmental damage.

Therefore, for dehydration treatment of crude oil tank farms, it is imperative to adopt highly efficient, safe and environmentally friendly technologies and methods. A comprehensive consideration of all relevant factors is required to achieve the goals of high treatment quality, low costs, safety and environmental friendliness.

Traditional Dehydration Technologies for Crude Oil Tank Farms and Their Characteristics

Traditional dehydration technologies for crude oil tank farms include sedimentation, hydrocyclone, and membrane-based processes.

Sedimentation TechnologyIts advantages lie in low cost, easy operation, and high treatment efficiency, which can effectively remove most suspended particles and heavy metal ions. However, it has several drawbacks: sedimentation tanks require a large footprint; the treatment effect is susceptible to factors such as flow rate and water quality; trace amounts of suspended solids and heavy metal ions still remain in the treated wastewater; and the generated sediment requires further disposal.

Hydrocyclone TechnologyIt boasts high treatment efficiency and a high removal rate of suspended solids and heavy metal ions in the treated wastewater. In addition, it does not require the addition of any chemical agents during the treatment process, resulting in minimal environmental pollution. Nevertheless, this technology is highly sensitive to environmental factors such as flow rate and temperature, which easily impair the treatment outcome.

Membrane-based TechnologyIts strengths include excellent removal performance, high purity of the treated water, low operating costs, and a small footprint. On the downside, it involves high initial investment; the filter membranes are prone to fouling and abrasion and thus require frequent replacement.

In summary, traditional dehydration technologies for crude oil tank farms each have their own merits and demerits, and the appropriate solution should be selected based on the actual application scenarios.

Sinokle's Dehydration Treatment Process in Crude Oil Tank Farms

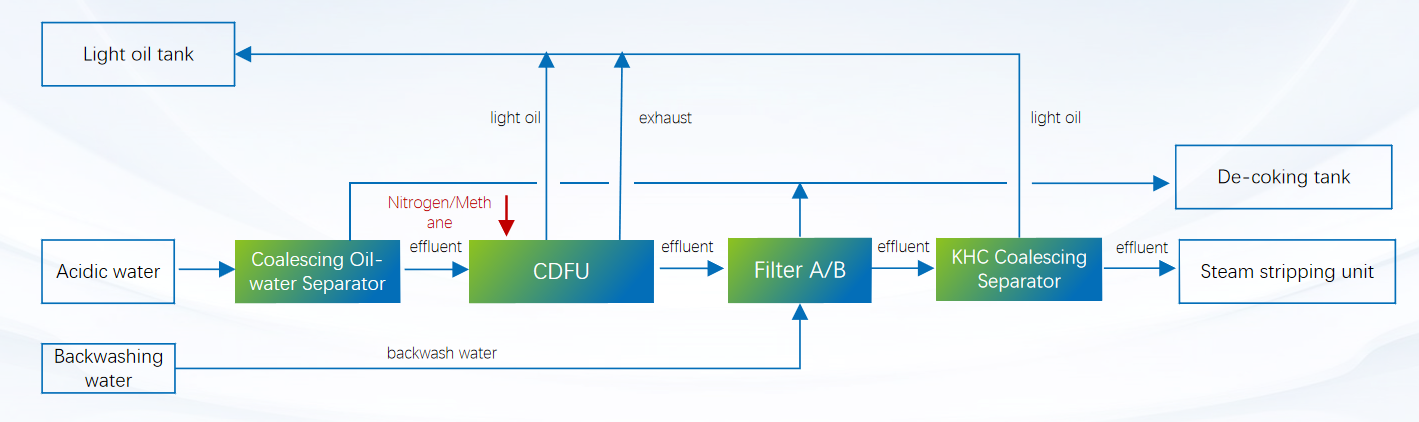

To address the challenges in dehydration treatment of crude oil tank farms and the limitations of traditional technologies, Sinokle Technology has developed an innovative integrated process. This proprietary process incorporates a suite of patented equipment, including the coalescing oil-water separator, the CDFU hydrocyclonic dissolved air flotation unit, filtration systems, and the KHC coalescing oil remover. By adopting a purely physical separation approach without the addition of any chemical agents, it achieves efficient emulsion breaking and oil-water separation, thus providing an effective solution to the aforementioned challenges.

Core Advantages of the Process

●The purely physical separation technology is stable and reliable, with an oil removal efficiency of over 95%.

●Achieving emulsion breaking and oil separation via a purely physical approach without any chemical agents, the recovered oil can be directly recycled back to crude oil tanks. This method eliminates secondary pollution and avoids the generation of oily sludge, thereby resolving environmental issues while creating economic benefits.

●The process flow is concise, the equipment structure is compact, and the floor space requirement is minimal.

●The skid-mounted equipment features high automation, simple operation and maintenance, a short construction period, and enables online implementation.

●It offers excellent shock resistance and operational stability, and can withstand significant fluctuations in water quality.

On-site Equipment