Sinokle’s Ozone Catalysts: Engineered for Performance in High-Challenge Wastewater Treatment

Today, as environmental regulations become increasingly stringent, industrial wastewater treatment—particularly the management of highly challenging wastewater—has become a critical component of corporate sustainable development. Leveraging its technical expertise in heterogeneous ozone catalysts, Sinokle has successfully developed two series of catalyst products: the carbon-based KHC-PC1001 and the silica-alumina-based (Si-Al-based) KHCF2001, offering efficient and reliable solutions for industrial wastewater treatment.

Technical Breakthrough: Dual Catalyst System Meets Diverse Needs

The core of Sinokle’s ozone catalysis technology lies in using solid catalysts to accelerate the decomposition of ozone into highly reactive hydroxyl radicals (•OH). These powerful radicals can completely oxidize organic pollutants into harmless small molecules. Through continuous innovation, Sinokle has achieved significant enhancements in catalyst performance.

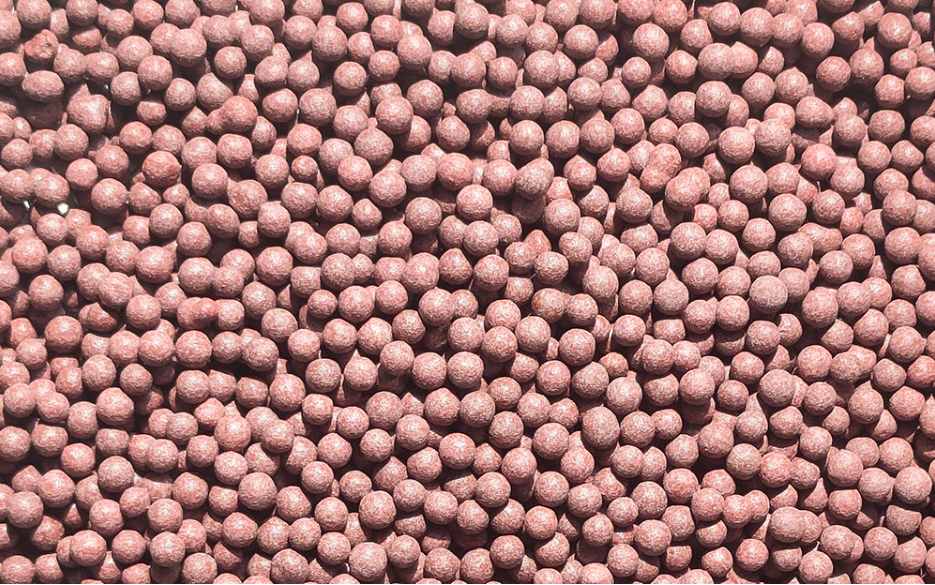

The KHC-PC1001 carbon-based catalyst features an exceptionally high specific surface area (1,286 m²/g), with uniformly dispersed metal oxide crystals on its surface providing abundant active sites. This catalyst demonstrates outstanding performance in treating oily wastewater. In a petrochemical project in Karamay, under an ozone dosage of 100 ppm, it achieved a COD removal efficiency exceeding 90%, reducing the residual oil content in the effluent to just 2.3 ppm.

The KHC-F2001 silica-alumina-based catalyst is fabricated using a proprietary sol-gel process, achieving a specific surface area of 250–300 m²/g—significantly higher than that of comparable products. Its innovative noble metal deposition technique and multi-stage precision-controlled sintering process ensure exceptional stability and catalytic efficiency.

Sinokle's ozone catalysts exhibit outstanding performance across multiple critical metrics.

In terms of mechanical strength, the KHC-F2001 achieves a crush strength of >150 N per grain and an annual wear rate of less than 2.5%, ensuring the lifespan exceeding five years. Regarding treatment efficiency, this technology improves ozone utilization by more than 20%, achieves COD removal rates above 85%, and delivers oxidation efficiency that is 2 to 5 times higher than conventional methods.

Notably, Sinokle's catalysts excel in treating high-salinity wastewater. In a landfill leachate treatment project in Zhangzhou, even with a salt concentration exceeding 30,000 mg/L, the KHC-F2001 catalyst reduced COD from 400 mg/L to below 60 mg/L and decreased color intensity from 500 to less than 5—all within just 30 minutes.

Proven Effectiveness: Technology Validated Across Multiple Industries

Sinokle's ozone catalysts have demonstrated remarkable results across a wide range of industrial applications. In landfill leachate treatment, the catalyst was successfully applied to aged leachate from a landfill site in Taizhou, achieving a COD removal rate exceeding 80% with an ozone dosage ratio as low as approximately 1.2.

In pharmaceutical wastewater treatment, a pharmaceutical manufacturer in Inner Mongolia implemented the KHC-F2001 catalyst. Within a hydraulic retention time of just 45 minutes, the system transformed dark brown pharmaceutical wastewater into clear, transparent effluent, reducing COD to below 200 mg/L and improving the BOD₅/COD (B/C) ratio from 0.1 to 0.37—significantly enhancing biodegradability.

Technical Highlights

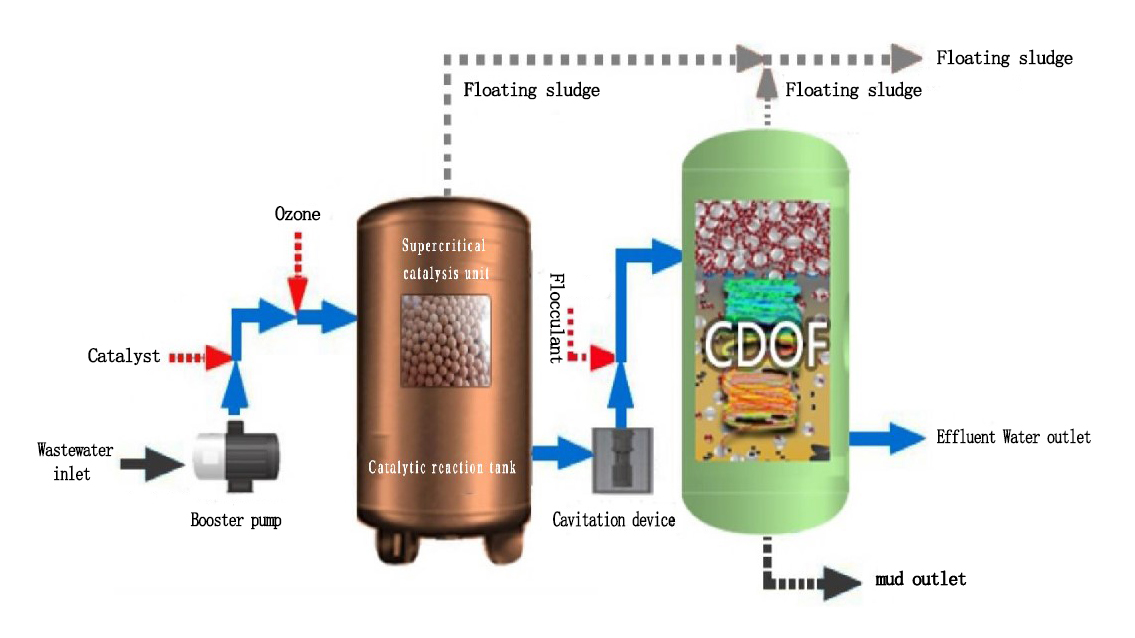

Sinokle's proprietary CDOF (Cyclonic Dissolved Ozone Flotation Unit) technology uniquely integrates multi-stage catalytic ozonation, cyclonic flow, and dissolved air flotation into a single, highly efficient system. This innovative approach offers several key advantages:

●Short contact time: Reactions complete within just 10–30 minutes

●Rapid treatment speed: 2 to 4 times faster than conventional ozonation processes

●Broad operational adaptability: Stable performance across a wide pH range of 3–10

By synergistically combining these advanced techniques, the CDOF system significantly enhances oxidation efficiency, solid–liquid separation, and overall process reliability.

The catalyst's unique super-hydrophilic surface significantly enhances the adsorption and diffusion of reactants on its active sites. Coupled with an intelligent integrated control system, Sinokle’s treatment units enable AI-powered real-time monitoring and fully unmanned operation, substantially reducing operational and maintenance costs.

Future Outlook: Continuous Innovation to Advance Environmental Sustainability

As a leader in heterogeneous ozone catalysis technology, Sinokle remains committed to deepening technological innovation, further optimizing catalyst performance, and expanding into new application domains. To date, catalysts have been successfully deployed in challenging wastewater treatment scenarios across multiple industries—including petrochemicals, pharmaceuticals, textile dyeing, and power generation—delivering clients cost-effective, high-performance environmental solutions.