Environmental Risks and Treatment Technologies of Oily Wastewater from Offshore Oilfields

1. Generation and Environmental Risks of Offshore Oily Wastewater

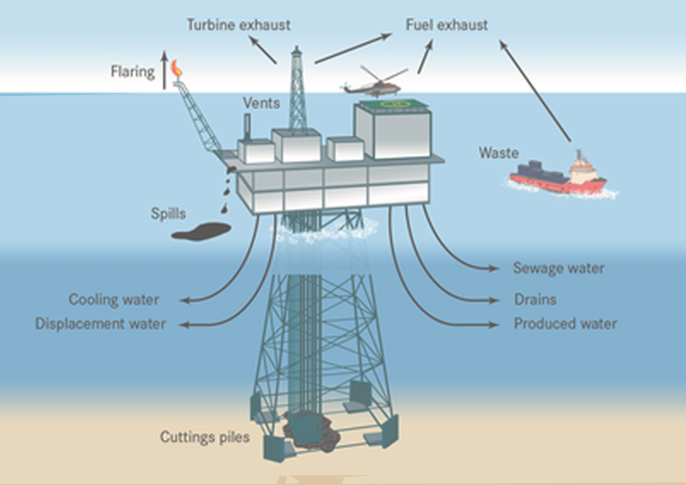

The production of oily wastewater from offshore oilfields is not a consequence of negligent operations; instead, it is an inevitable by-product of offshore oil exploration and extraction activities—sectors that underpin the stability of the global energy supply and economic system. Specifically, oily wastewater is generated throughout the entire lifecycle of offshore crude oil exploitation, ranging from offshore drilling, well completion, and oil production to subsequent equipment maintenance and crude oil preliminary treatment processes. In terms of output volume, oily wastewater stands as the most prominent waste stream in offshore oil and gas operations. Improper management and unauthorized discharge of such offshore oily wastewater into the marine environment will inevitably trigger severe marine pollution, exerting far-reaching adverse effects on both marine aquatic ecosystems and coastal terrestrial ecological communities that are closely linked to marine resources.

The global volume of oily wastewater generated from offshore oilfields is staggering, with millions of liters produced daily across major offshore oil-producing regions worldwide. A core focus in addressing the challenges posed by this massive volume of offshore oily wastewater lies in its complex and hazardous composition. Offshore oily wastewater is typically a heterogeneous mixture dominated by various hydrocarbon compounds, including alkanes, aromatic hydrocarbons, and polycyclic aromatic hydrocarbons (PAHs). A significant subset of these hydrocarbons exhibits inherent toxicity, mutagenicity, or carcinogenicity. These harmful contaminants can easily accumulate through the marine food chain—from plankton to large marine organisms—and ultimately pose substantial health risks to both marine animal populations and human beings who rely on marine products for sustenance. Consequently, the remediation and proper treatment of offshore oily wastewater are not merely optional measures but indispensable prerequisites for preserving marine ecological balance and safeguarding long-term environmental sustainability.

2. Conventional Treatment Technologies for Offshore Oily Wastewater

Historically, the management of offshore oily wastewater has predominantly relied on conventional treatment methodologies, which can be categorized into physical, chemical, and biological processes.

Due to the unique operational constraints of offshore platforms, physical separation techniques—such as skimming and dissolved air flotation (DAF)—are among the most widely employed primary treatment methods, as they are relatively compact and easy to operate. These physical processes are primarily used to separate free-floating oil fractions from the aqueous phase.

For emulsified oil, which is more recalcitrant to removal due to its stable colloidal dispersion in water (a common characteristic of offshore oily wastewater caused by high-pressure drilling and turbulent oil-water mixing), chemical processes like coagulation and flocculation are often utilized. These chemical treatments work by neutralizing the surface charge of oil droplets, promoting their aggregation into larger flocs that are easier to separate.

Biological treatment approaches, by contrast, leverage the metabolic capabilities of oil-degrading microorganisms to break down oil-based contaminants into harmless substances like carbon dioxide and water, offering a more eco-friendly and cost-effective alternative to chemical-intensive methods in the long run. In recent years, technological advancements in wastewater treatment have made remarkable strides in addressing the unique challenges posed by the large volume and complex composition of offshore oily wastewater, significantly enhancing both the efficiency and effectiveness of on-platform treatment processes.

3. Collection and Separation Procedures of Offshore Oily Wastewater

The proper collection, separation, and advanced treatment of offshore oily wastewater are critical steps in mitigating marine pollution and ensuring the safe handling of industrial waste streams in offshore oil operations. Offshore oily wastewater is typically contaminated with a complex mixture of hydrocarbons, suspended solid particles (such as drilling cuttings), heavy metals, and other harmful pollutants. These contaminants are generated during multiple key stages of the offshore oil and gas production process, including offshore drilling operations, well production activities, crude oil-water separation processes, and equipment cleaning and maintenance procedures. To achieve effective treatment and compliant disposal, the management of offshore oily wastewater entails the implementation of a series of sequential and essential procedures tailored to the offshore environment. Initially, offshore platforms collect wastewater from a diverse range of sources within the production site, including oil-water separators, storage tanks, drilling mud circulation systems, and equipment washing areas. This collected wastewater usually consists of two main components: produced water, which is naturally occurring in offshore oil and gas reservoirs and is co-extracted with hydrocarbons during production, and process water, which is utilized in various on-platform industrial operations such as cooling, cleaning, and steam generation for enhanced oil recovery.

Following the collection phase, the separation of oil from water in offshore settings is typically accomplished through a combination of chemical and physical processes optimized for limited platform space. Gravity-driven separation technologies, such as API (American Petroleum Institute) separators and horizontal separators, are widely used in offshore platforms to exploit the density difference between oil and water. These devices are designed with compact structures to fit the limited space on offshore platforms, allowing oil to rise to the surface where it can be efficiently skimmed off. In addition to physical separation, chemical treatments are often employed to enhance the separation efficiency, particularly for stable oil-water emulsions that are prevalent in offshore oily wastewater. These chemical interventions include the addition of coagulants (such as polyaluminum chloride), flocculants (such as polyacrylamide), and demulsifying agents (such as polyether demulsifiers), which work synergistically to break down stable oil-water emulsions and promote the aggregation of oil droplets. After the oil separation stage, the remaining produced water undergoes further purification through media filtration processes (such as sand filtration or membrane filtration) to remove any residual suspended particles and trace oil contaminants. Efficient oil-water separation in offshore operations is not only critical for ensuring the long-term sustainability of the offshore oil and gas industry but also for complying with stringent international and regional environmental regulations (such as the International Maritime Organization's MARPOL Convention) and minimizing the ecological footprint of offshore industrial operations.

4. Unique Challenges of Offshore Oily Wastewater Discharge

Compared to onshore oil operations, offshore oil and gas facilities typically discharge larger volumes of oil-contaminated wastewater into the marine environment. This discrepancy can be primarily attributed to the unique geographical and operational constraints that severely hinder the deployment of advanced and large-scale treatment technologies—such as full-scale biological reactors—on offshore platforms. Key challenges specific to offshore settings include extremely limited spatial availability on platforms, significantly higher operational and maintenance costs (due to the need for marine-grade equipment and logistical support), and complex logistical difficulties associated with the transportation of treatment chemicals, equipment parts, and waste residues to and from offshore locations. These constraints often prevent the full integration of sophisticated and comprehensive wastewater treatment systems on offshore platforms, thereby increasing the likelihood of direct discharge of inadequately treated oily wastewater into marine ecosystems. As a result, offshore wastewater discharges contribute substantially to marine pollution, which in turn disrupts marine biodiversity (e.g., causing coral bleaching and reducing the population of plankton and benthic organisms), alters the structure and function of aquatic food webs, and poses a serious threat to coastal fisheries and the livelihoods of coastal communities that depend heavily on marine resources for their economic survival.

5. Advanced Oxidation Processes (AOPs) for Offshore Oily Wastewater Treatment

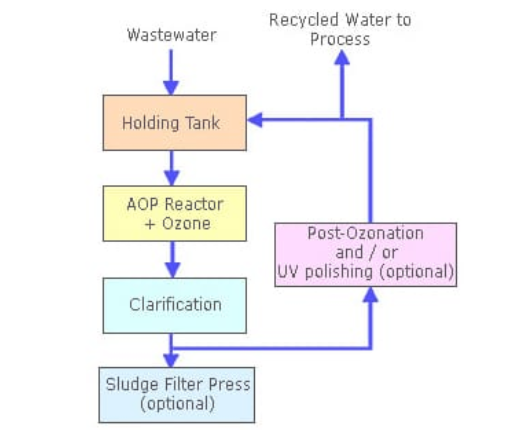

Oxidation processes represent a class of chemical treatments that have gained increasing attention in offshore oily wastewater treatment due to their high efficiency and adaptability to compact spaces. These processes involve the transfer of electrons between reactants, leading to the breakdown and mineralization of persistent pollutants in oily wastewater. The oxidizing agents used in these processes possess sufficient oxidative potential to decompose even the most complex and refractory organic compounds (such as polycyclic aromatic hydrocarbons) present in offshore oily wastewater. Advanced Oxidation Processes (AOPs) constitute a subset of oxidation technologies that are specifically designed to remove organic and inorganic contaminants from water and wastewater through oxidation reactions mediated by hydroxyl radicals (•OH). Hydroxyl radicals are highly reactive and non-selective species that can oxidize a wide range of pollutants, converting them into harmless by-products such as carbon dioxide, water, and inorganic salts. The term "Advanced Oxidation Processes" encompasses a diverse range of technologies that are suitable for offshore applications due to their compact design, including those based on ozone (O₃), hydrogen peroxide (H₂O₂), ultraviolet (UV) radiation, and Fenton's reagent (a combination of iron ions and hydrogen peroxide).

5.1 Ozone-Based Oxidation Technology

Among these AOP technologies, ozone (O₃) is recognized as a highly potent oxidizing agent, capable of effectively eliminating a broad spectrum of organic contaminants in offshore oily wastewater. It exhibits exceptional efficiency in addressing non-biodegradable organic materials that are commonly present in offshore oily wastewater and are difficult to remove using conventional physical or biological methods. Ozone achieves this by breaking the chemical bonds of complex organic pollutants, decomposing them into smaller, more biodegradable molecules. This not only reduces the toxicity of the wastewater but also facilitates the subsequent removal of residual contaminants through follow-up treatment processes (such as biological treatment or filtration). Additionally, ozone treatment does not produce secondary pollutants like sludge, which is a significant advantage for offshore platforms where sludge disposal is logistically challenging and costly. These characteristics make ozone-based oxidation an increasingly promising technology for offshore oily wastewater treatment.