Sinokle's CDOF Process: Revolutionizing Industrial Wastewater Treatment

With the rapid advancement of industrial development and urban construction, water pollution has become increasingly prominent, and wastewater purification has emerged as an urgent environmental issue to address. Conventional wastewater treatment methods often face challenges such as limited treatment efficiency, high costs, and unstable performance, creating an urgent need for more efficient and eco-friendly purification solutions. Against this backdrop, the advanced catalytic ozonation technology—an innovative water treatment method that has garnered significant attention—is being extensively researched and promoted.

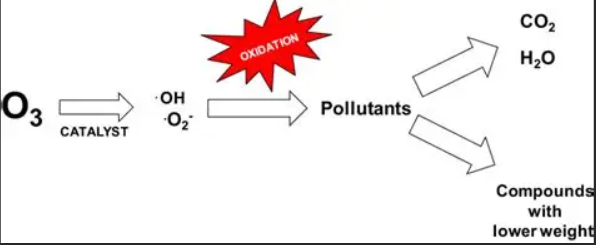

This technology utilizes the free hydroxyl radicals generated by ozone decomposition to oxidize and break down organic pollutants. The hydroxyl radicals produced during the reaction possess a redox potential of up to 2.8V (compared to 2.07V for ozone molecules), with oxidizing power second only to fluorine. They can act on impurities in water in various forms (including dissolved, emulsified, suspended, colloidal, and microbial forms), converting complex organic compounds into low-molecular-weight organics, acids, and aldehydes. Simultaneously, it significantly improves water turbidity, color, and odor, while achieving efficient sterilization.

The direct ozonation method adopted in the early stages has limitations, including a slow reaction rate, obvious selectivity in pollutant removal, low ozone utilisation efficiency, and high treatment costs. In contrast, the advanced catalytic ozonation system significantly improves ozone utilization efficiency and decomposition performance, has almost no selectivity restrictions on various pollutants, features outstanding comprehensive purification capacity, and does not cause secondary pollution—thus showing broad prospects in the field of wastewater treatment. Currently, this process has been successfully applied in various wastewater treatment scenarios, particularly demonstrating excellent performance in the treatment of challenging wastewater, such as landfill leachate, petrochemical wastewater, and pharmaceutical wastewater.

Development and Application of Advanced Ozonation Technologies:

·Advanced catalytic oxidation (e.g., O3/H2O2)

·O3/UV advanced oxidation

·O3/ultrasonic advanced oxidation

·O3/activated carbon advanced oxidation

·O3/metal catalyst advanced oxidation, etc.

Building on existing advanced ozonation technologies, Sinokle has innovatively developed the CDOF process (Cyclonic Dissolved Ozone Flotation Unit), which organically integrates advanced catalytic ozonation, cyclone technology, and dissolved air flotation technology. Relying on independently developed supercritical catalytic materials and high-efficiency heterogeneous catalysts, it achieves cavitation supercritical catalytic reactions. This system completes high-efficiency catalytic ozonation in a fully enclosed, automatically pressurized reaction device, and can be widely applied to the efficient and comprehensive purification of various refractory wastewater.

Advantages of Sinokle's CDOF

1. The pioneering product integrating multiple technologies including: ozone catalytic oxidation, cyclonic dissolved air flotation, coagulation and others, which efficiently removes COD, suspended solids (SS), colloids, bacteria, viruses, etc.

2. Multi-stage, multi-dimensional and multiple ozone catalytic oxidation reactions: including pressurized catalytic reaction, homogeneous and heterogeneous catalytic oxidation, hydrodynamic cavitation catalysis, micro-pressure catalytic oxidation, cyclonic fluidization reaction and other processes, with stable and reliable effects.

3. Special patented structural reactor with extremely fast reaction rate (residence time < 15 minutes compared with 90 minutes for traditional processes), operates in a closed and pressurized manner, free from ozone leakage, safe and environmentally friendly.

4. Ozone utilization rate reaches over 99.98%, and ozone dosage ratio is 0.5~1.2 (2~4 for traditional processes) — only 1/5 to 1/2 of traditional processes, with operating costs at 1/3 to 1/2 of traditional processes.

5. Adopts DCS/PLC fully automatic control technology to precisely control ozone dosage, reaction liquid level, pressure, tail gas concentration, etc., and can automatically optimize according to water quality to reduce operating costs.

6. Uses special catalysts with high activity, high strength, large specific surface area, strong pollution resistance, wide pH adaptability (acidic and alkaline conditions), and long-term effectiveness.

7. Unique catalyst backwashing, activation and regeneration process ensures long-term stable performance.

Application of CDOF

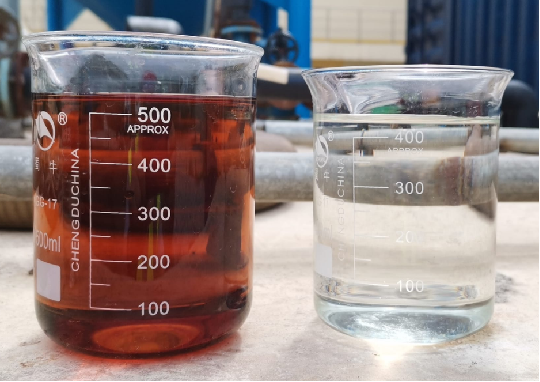

In a landfill leachate treatment project of a waste incineration power plant in Shiyan, Hubei Province, the integrated CDOF advanced catalytic ozonation and dissolved air flotation equipment was adopted, with a daily treatment capacity of 300m³. The influent to the system was the effluent from the upstream MBR process, with a COD of approximately 1300 mg/L. After treatment by the CDOF device, the effluent COD was reduced to below 400 mg/L, the chromaticity was lower than 30 degrees, and the odor was eliminated. Subsequent treatment by the biological treatment unit resulted in final effluent with COD ≤ 20 mg/L, ammonia nitrogen < 1 mg/L, and total phosphorus < 0.2 mg/L. All indicators stably met the Class Ⅲ surface water quality standard, achieving compliance with discharge regulations.