Biofilm Process: A Key Technology in Modern Sewage Treatment

The Evolution of Sewage Treatment

The history of sewage treatment dates back to ancient Rome. During that period, the environmental capacity was large, and the self-purification ability of water bodies was sufficient to meet human water needs—people only needed to address drainage issues. With the advent of the Industrial Revolution, however, water pollution became increasingly severe. From the late 19th century to the early 20th century, the development of microbiology led people to recognize the impact of pathogens on water quality, prompting the adoption of scientific methods for water disinfection.

In the 21st century, growing awareness of environmental protection and continuous technological progress have driven water treatment technologies toward high efficiency, energy conservation, and environmental friendliness. Physical filtration technologies such as ultrafiltration, nanofiltration, and reverse osmosis are widely used in the advanced treatment of industrial and domestic water. Meanwhile, biological treatment technologies like Membrane Bioreactors (MBR) have been applied in municipal sewage treatment. MBR combines microbial treatment with membrane separation technology, providing strong technical support for water reuse.

Biofilm Process: Principle, Classification and Advantages

Both the biofilm process and the activated sludge process are methods that use microorganisms to remove organic matter from sewage. In the activated sludge process, microorganisms grow in a suspended state, so the treatment system is also called a suspended growth system. In contrast, microorganisms in the biofilm process attach to the surface of certain substances, making the system an attached growth system. The biofilm process mainly includes biofilters, rotating biological contactors, and fluidized bed bioreactors.

The basic principle of the biofilm process is to achieve contact between sewage and biofilm through their relative movement, enabling solid-liquid mass exchange. Organic matter undergoes biological oxidation within the biofilm, purifying the sewage. Compared with the activated sludge process (where microorganisms grow in suspension), the biofilm process offers several advantages:

• It has high nitrogen removal capacity due to the presence of numerous nitrifying bacteria;

• The diverse microorganisms in the biofilm (including aerobic bacteria, anaerobic bacteria, fungi, and algae) enable broad-spectrum pollutant removal;

• A large number of microorganisms occupy the entire reactor space, resulting in much higher biomass per unit volume than the activated sludge process and thus greater treatment capacity per unit volume;

• The food chain of microorganisms in the biofilm process is longer than that in the activated sludge process, and most sludge produced is consumed by organisms, leading to less excess sludge;

• The system is easy to maintain, has low energy consumption, and does not require sludge recirculation;

• Its complex microecology provides strong resistance to changes in hydraulic and organic loads, ensuring stable operation.

Biological Contact Oxidation Process

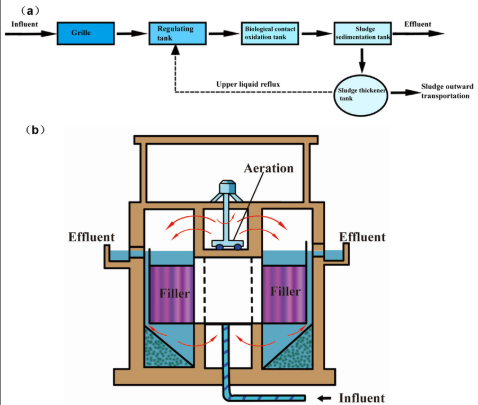

The biological contact oxidation process is a sewage treatment technology developed in the early 1970s. It is widely used in treating domestic sewage and industrial wastewater from food processing, as well as in the biological pretreatment of slightly polluted surface raw water. In China, this technology has also been extensively applied—not only for domestic sewage but also for industrial wastewater from petrochemicals, pesticides, printing and dyeing, textiles, papermaking, and food processing—achieving excellent treatment results.

The biological contact oxidation process can be divided into two types:

1. Submerged biofilter: Fillers are placed in a tank, and oxygenated sewage submerges all fillers and flows through them at a certain velocity. Sewage makes extensive contact with the biofilm covering the fillers, and organic matter in the sewage is removed through the metabolic activity of microorganisms on the biofilm.

2. Contact aeration process: The same aeration method as in an aeration tank is used to supply oxygen to microorganisms and achieve mixing and stirring. This is equivalent to adding fillers for microbial attachment in an aeration tank, hence the name "contact aeration process."