Tackling High Water-Cut Challenges: Sinokle’s Integrated Produced Water Reinjection Solution

1. Overview of Produced Water Reinjection

Against the backdrop of continuously tightening national environmental regulations, oilfields across the country are progressively shifting toward total pollutant control and compliant water reinjection as key development strategies. Facing increasingly stringent environmental requirements, produced water treatment systems must achieve consistent and stable operation to guarantee compliance with discharge standards and eliminate any risk of leakage. Moreover, as oilfields enter the mid-to-late stages of development, the water cut in produced fluids continues to rise, placing higher demands on the efficiency, compactness, and reliability of treatment equipment. However, current produced water treatment systems commonly suffer from weak shock resistance, significant fluctuations in performance, and complex operation and maintenance procedures—challenges that hinder further advancement in oilfield production. Consequently, effective produced water reinjection has become an urgent necessity in the field of oilfield produced water management.

2. Conventional Produced Water Reinjection Technologies and Their Limitations

Traditionally employed produced water reinjection processes exhibit notable shortcomings. For instance, configurations combining inclined plate settlers with walnut-shell or fiber-ball filters offer good permeability but are prone to reduced system reliability and diminished shock resistance due to chemical dosing requirements and issues associated with aged oil, making it difficult to maintain consistent effluent quality. Another common approach—using settling tanks combined with induced gas flotation (IGF), fiber-ball or multimedia filters, and ceramic membranes—not only involves a complex process flow and high energy consumption but also incurs elevated operating costs, while still suffering from poor shock resistance and significant effluent variability. Furthermore, processes that integrate settling tanks, IGF, fiber-ball or multimedia filters, and ultrafiltration (UF) membranes struggle to operate effectively under high-temperature conditions. The membrane materials used often exhibit poor compatibility with crude oil, resulting in inadequate long-term operational stability. Additionally, high salinity exacerbates operational and maintenance challenges, further increasing costs.

3. Advantages of Sinokle's Produced Water Reinjection Treatment Technology

Sinokle has developed a next-generation produced water reinjection treatment process centered around its proprietary hydrocyclone dissolved air flotation (DAF) technology, integrating advanced components such as the HAC hydrocyclone separator, high-precision activated filters, and SIC microfiltration membranes to deliver an integrated treatment solution for oilfield produced water. This process enables short-process treatment of produced fluids without the need for chemical additives, ensuring stable system operation and effluent quality that meets reinjection standards. Additionally, the discharged oil phase exhibits low water content, and the solid residues can be safely dewatered via filter presses and transported offsite for disposal.

Figure 1. Equipment for produced water reinjection treatment

4. Two Process Configurations of Sinokle's Produced Water Reinjection Treatment Technology

Considering the varying project conditions, process requirements, and treatment challenges, Sinokle has developed two distinct process configurations capable of achieving Class A2 and Class A1 standards for treated produced water, respectively.

Configuration 1: Two-stage HAC + two-stage CDFU + two-stage KFM filters — this configuration meets the Class A2 standard.

Configuration 2: Two-stage HAC + two-stage CDFU + SiC membrane filter + CDFU — this configuration achieves the Class A1 standard.

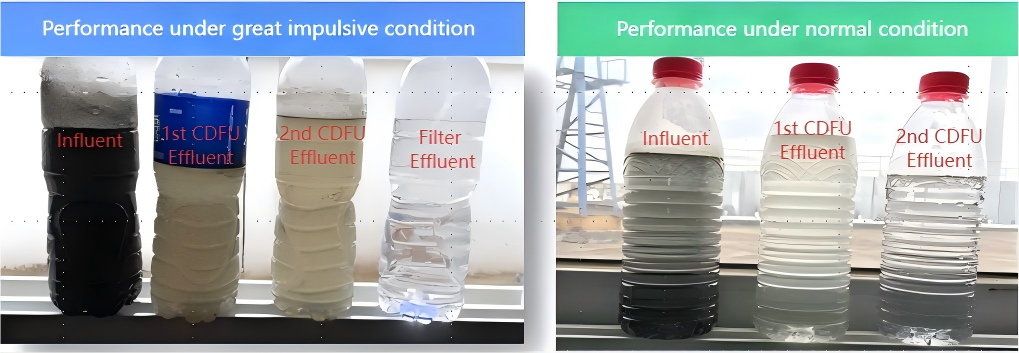

Figure 2. Treatment Performance

5. Key Features of Sinokle's Produced Water Reinjection Treatment Process

(1) Proven and robust technology with strong shock resistance, delivering stable and reliable performance.

(2) Purely physical demulsification—no chemical additives, no aged oil accumulation, and no secondary pollution, resulting in excellent environmental benefits.

(3) Compact and efficient process flow: short treatment sequence, small footprint, fewer operating units, simple operation, and relatively low operating costs.

(4) Dual-stage hydrocyclone oil-water separators combined with dual-stage hydrocyclone dissolved air flotation (CDFU) significantly enhance the stability and reliability of downstream treatment.

(5) Advanced filtration technologies ensure consistent compliance with stringent water quality standards.

These solutions not only guarantee effluent quality that meets national regulatory requirements but also contribute to improved oilfield production efficiency and enhanced overall economic returns.