Why SiC Membranes Are Leading the Future of Industrial Wastewater Treatment?

In today's world, where environmental pollution is becoming increasingly severe, wastewater treatment has become a crucial measure for safeguarding water resource security and ecological environments. Among the many wastewater treatment technologies available, SiC membrane filters have emerged as a standout solution—renowned for their unique advantages and broad range of applications—shining brightly in the field of wastewater treatment.

Figure 1. On-site SiC Membrane Filter

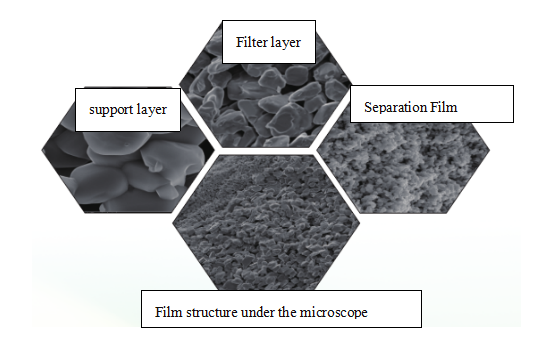

SiC membrane filters, formally known as silicon carbide ceramic membrane filters, are microfiltration and ultrafiltration products manufactured from silicon carbide (SiC)—an inorganic carbon-based material renowned for its superior hydrophilicity. These filters are characteristic of exceptional fouling resistance, extremely high filtration flux, outstanding chemical stability, and remarkable mechanical strength. The membrane core features a honeycomb-structured design, which not only ensures high mechanical strength, high packing density, and excellent sealing performance but also facilitates easy installation and maintenance—significantly reducing both operational costs and maintenance complexity.

The principle of SiC membrane filters mainly relies on their microfiltration and ultrafiltration capabilities to effectively retain impurities such as suspended solids (SS), particles, oils, and fats in wastewater, thereby achieving the goal of water purification. With extremely small pore sizes, the filtering precision reaches below 1.0 ㎛ (even down to 40 nm), ensuring high-quality effluent. Additionally, due to the excellent hydrophilicity of SiC material—with a water contact angle as low as just 0.3 degrees—they possess strong resistance to oil pollution, maintaining high filtration efficiency even in the condition of high oil content.

Figure 2. KSC-40/1200-PD Film Element

Beyond their superior filtration performance, SiC membrane filters boast several unique features. Firstly, they have a high water flux, approximately 3 to 4 times that of traditional ceramic membranes, significantly enhancing wastewater treatment efficiency. Secondly, by employing dynamic continuous membrane regeneration technology, they exhibit good membrane regenerability and longevity, reducing the frequency and costs associated with filter replacements. Moreover, SiC membrane filters are characterized by excellent chemical stability and resistance to high pressure and temperatures, enabling stable operation in harsh wastewater environments for extended periods, with a maximum operating temperature up to 800°C.

In terms of application scenarios, SiC membrane filters, thanks to their unique advantages and characteristics, are extensively utilized in end-treatment processes across various fields including oilfield production reinjection water treatment, deep treatment of petrochemical wastewater, and deep treatment of wastewater from industries like metallurgy and textiles. In oilfield production reinjection water treatment, SiC membrane filters effectively remove suspended solids, particles, and oils from wastewater, ensuring that the quality of reinjection water meets standards and preventing contamination of geological formations. In the deep treatment of petrochemical wastewater, these filters further purify wastewater by removing hard-to-degrade organic compounds and inorganic salts, improving effluent quality, and achieving compliance for discharge or reuse. Similarly, in the deep treatment of wastewater from metallurgical and textile industries, SiC membrane filters play a crucial role, providing significant support towards sustainable development in these sectors.

To sum up, SiC membrane filters demonstrate tremendous potential and value in the field of wastewater treatment due to their unique advantages and broad range of applications. As technology advances and environmental awareness grows, it is believed that SiC membrane filters will gain even wider application and promotion, making greater contributions to environmental protection efforts.