Oilfield Wastewater Treatment Process and Application with CDFU as the Core

As the global energy structure transforms, the rise of renewable energy undoubtedly poses challenges to the oil industry. However, according to authoritative predictions, despite the substantial increase in the share of renewable energy, oil will continue to occupy an important position in the global energy system for the next decade. As the world's largest energy consumer, China's energy consumption growth accounts for 35% of the global net increase, suggesting that oil exploration activities will continue for some time. Nevertheless, with the deepening of oil exploration, the development of "three-low" (low porosity, low permeability, and low saturation) reservoirs has increasingly highlighted the issue of produced water, making it increasingly difficult to treat.

Produced water refers to the groundwater extracted along with crude oil from the formation, containing a large amount of suspended solids, oil, dissolved minerals, and harmful substances. If these wastewaters are directly reinjected underground without proper treatment, they can cause blockages in reservoir channels, increase subsequent water injection difficulty, reduce crude oil production, and contaminate the environment. Therefore, the effective treatment of produced water has become a bottleneck problem restricting the development of the oil exploration industry.

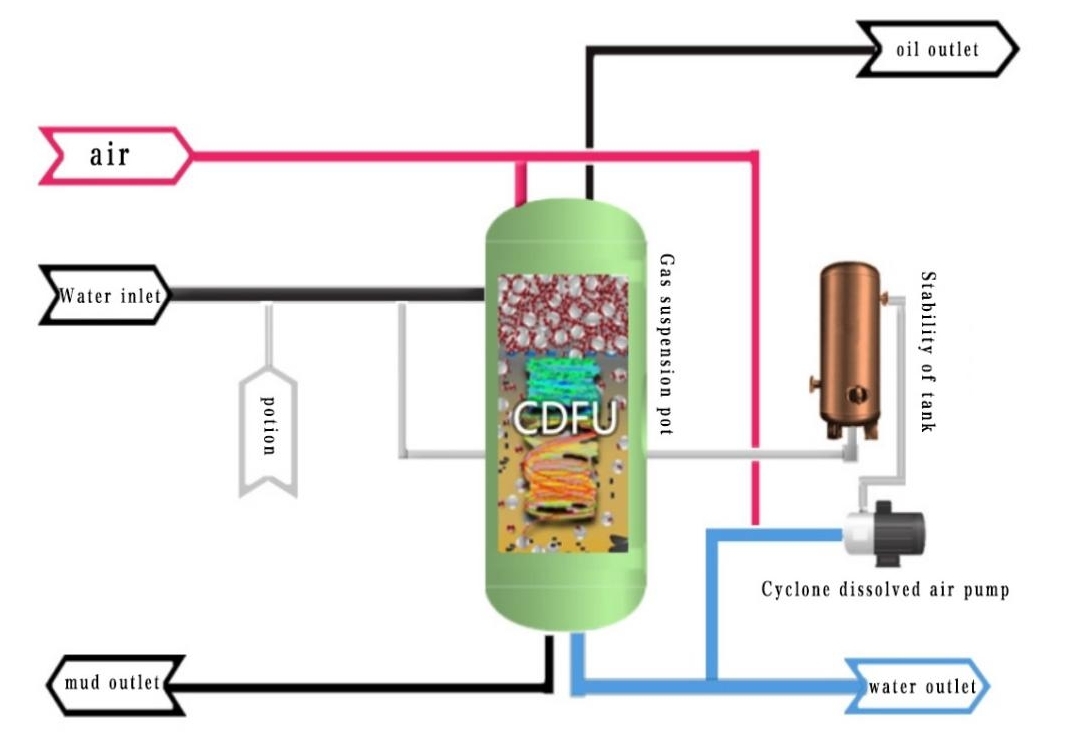

To address this challenge, numerous researchers and manufacturers at home and abroad have conducted extensive research, with the Cyclonic Dissolved Gas Flotation (CFU) technology gaining attention due to its efficiency and compactness. Based on this, we have developed a new generation of oilfield wastewater treatment equipment, the CDFU (Cyclonic Dissolved Gas Flotation Unit), by integrating advanced technologies such as ultra-micro bubble generation, dissolved air flotation, and coalescence.

The CDFU equipment integrates multiple technologies into one unit, featuring high oil removal efficiency, excellent removal of suspended solids, pressurized and enclosed operation, safety, environmental friendliness, and skid-mounted, automated, and informatized advantages. Its working principle involves injecting ultra-micro bubbles into the wastewater, causing the bubbles to collide and adhere to the oil droplets and suspended solids in the wastewater, forming air-float aggregates with a density less than water that rise to the surface and are removed. Additionally, the CDFU equipment employs cyclonic technology, which further enhances the removal efficiency of oil droplets and suspended solids through the centrifugal force generated by the cyclonic flow.

In practical applications, the CDFU equipment has demonstrated outstanding performance. For example, an oilfield using CDFU equipment for produced water treatment achieved water quality that met reinjection standards, not only solving the issue of reservoir channel blockage but also increasing crude oil production. Moreover, the CDFU equipment boasts small footprint, low operational costs, and convenient maintenance, earning it favor among oilfield users.

CDFU Application Case in Oilfield Wastewater Treatment

Apart from the treatment of oilfield produced water, CDFU equipment has widespread applications in pressure backflush fluid, landfill leachate, oil-containing firefighting wastewater, medical wastewater, and many other fields. Its efficient and environmentally friendly characteristics make CDFU equipment an ideal choice for treating various types of refractory organic wastewaters.

In summary, the oilfield wastewater treatment process with CDFU as the core offers new ideas and methods for solving the issue of produced water due to its efficiency, compactness, and environmental friendliness. With continuous technological advancements and expanding application fields, CDFU equipment is poised to play an increasingly significant role in the future.